An Overview on RFID Technology Instruction and Application

RFID (Radio Frequency IDentification) is a wireless communication technology used to capture data, which may be linked to different identification attributes (serial number, position, colour, date of purchase, etc.) of entities carrying RFID labels (tags). The data collection process is based on an exchange of electromagnetic waves between RFID tags and RFID interrogators (readers). This Automatic Identification and Data Capture (Auto-ID) technology is capable of providing further labelling granularity when compared to barcodes and previous Auto-ID technologies. For instance, with RFID, it is possible to allocate different identification codes for similar items, and different levels of identification allowing better visibility and tractability in logistical and manufacturing processes. Over the past five years, several groups (economic, social, military, healthcare, and political) became aware of the potential to innovate and improve the efficiency of their processes using RFID technology. The use of RFID tags is increasing, and their communication performances, and level of standardisation, are being continuously refined. For instance, the development of new communication protocols such as, the Ultra High Frequency Generation 2 (UHF Gen 2), brought an unprecedented level of reliability, and information security to this technology.

RFID systems made of software components (tags, antennas, middleware).

At this stage, operation frequencies, RFID tags reading range, RFID antenna locations, power control, information privacy and security issues are among few factors to be adjusted, for efficient data capture, and reliable RFID interrogation zones design. The control facet deals mainly with RFID system real-time control (middleware link to other enterprise applications, EPC database, graphical user interfaces), and business intelligence rules implementation (information processing, system response to RFID tag triggered events, control rules, algorithms).

-

Generic architecture of a basic RFID system

A basic RFID system is generally made of the following components:

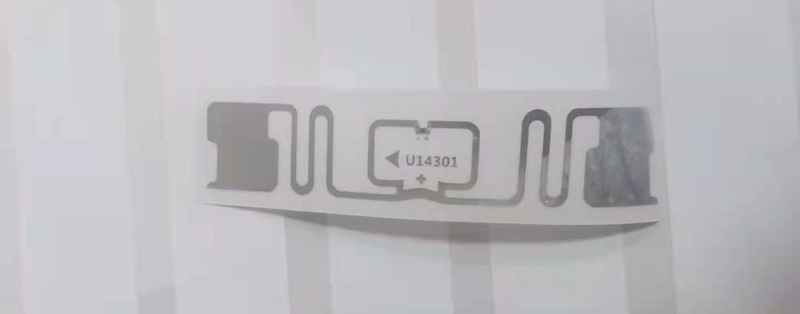

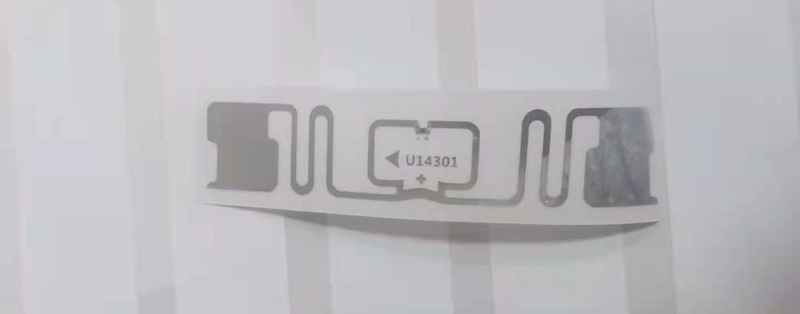

RFID tags fixed to entities with unique electronic product code (EPC) per entity (wireless RFID network); Networked RFID readers, and real time databases; RFID antennas for information exchange between the tags wireless network and middleware/control platforms. There are two types of RFID tags: passive and active. A passive RFID tag is powered by the electromagnetic energy, radiated from RFID reader antennas, based on backscattering.

Most applications of RFID technology are widely used in manufacturing sector: production monitoring and control, and supply chains management. Other studies regarded RFID use as an avenue to simplify the control and management of complex systems such as: efficient management of recycling process , drugs traceability for pharmaceutical industry, bookstore inventory control, patients flow management in health care facilities , airport baggage routing and handling , food safety and labelling, and in-building asset tracking and management . The growing number of these applications confirms the capability of RFID systems to achieve operational efficiency and reduce costs. RFID technology must be assimilated and effectively integrated to effectively manage the

production of goods and services.